Lm7 4 pin to 1 cable alternator wiring diagram

In the world of automotive engineering, understanding the wiring system of an alternator is crucial for both enthusiasts and professionals. For those working with the LM7 engine, which is commonly found in various GM vehicles, a comprehensive understanding of its alternator wiring can greatly enhance your ability to troubleshoot and customize automotive electrical systems. This article delves into the LM7 4-pin to 1 cable alternator wiring diagram, explaining its components, function, and wiring techniques to ensure optimal performance.

Overview of the LM7 Engine

The LM7 engine is a 5.3L V8 powerhouse that was part of GM’s Gen III small block engine family. Known for its durability and performance, the LM7 is often found in GM trucks and SUVs from the early 2000s. The alternator in the LM7 plays a crucial role, converting mechanical energy from the engine into electrical energy to power the vehicle’s electrical systems and recharge the battery.

The Role of the Alternator

An alternator serves several essential functions:

- Charging the Battery: It keeps the battery charged, ensuring that it can start the engine and power electrical accessories when the engine is off.

- Powering Electrical Systems: The alternator provides electricity to various electrical components, such as headlights, radio, and air conditioning, while the engine runs.

- Voltage Regulation: It maintains a consistent voltage level to prevent damage to sensitive electronic components.

Understanding the 4-Pin Configuration

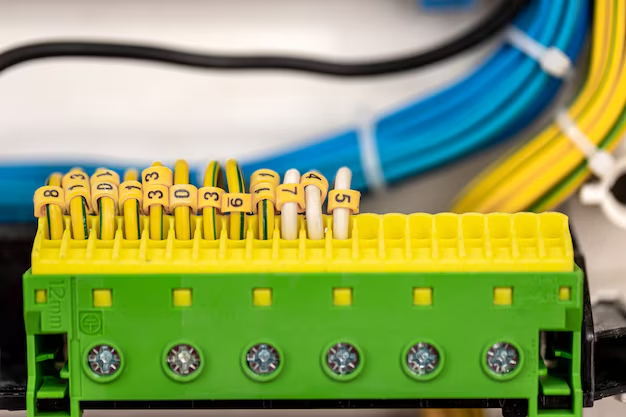

The LM7 alternator is designed with a 4-pin connector, which typically consists of the following terminals:

- Battery (B+) Terminal: This terminal connects directly to the battery and provides the primary source of electrical power.

- Ground (Gnd) Terminal: This is the grounding point for the alternator, crucial for circuit completion.

- Ignition (IG) Terminal: This terminal signals the alternator to start charging once the engine is running.

- Signal (S) Terminal: This terminal sends a signal to the vehicle’s computer to monitor alternator performance.

The 4-Pin to 1 Cable Concept

In some automotive modifications or repairs, you may encounter a scenario where the 4-pin connector is modified to a simpler 1-cable configuration. This is often done to replace a malfunctioning alternator or to simplify the wiring during a custom installation. However, it is essential to understand that this alteration may compromise certain functions, such as voltage regulation and communication with the vehicle’s computer.

Wiring Diagram Breakdown

To ensure a clear understanding of the LM7 alternator wiring, let’s break down the typical wiring diagram for the 4-pin configuration:

Material Requirements

Before delving into the wiring process, ensure that you have the following materials:

- Automotive-grade wiring (AWG 10 or larger)

- Additional connectors and terminals

- Electrical tape or heat shrink tubing

- Multimeter

- Wire crimping tool

- Soldering iron (optional for permanent connections)

Step-by-Step Wiring Instructions

- Disconnect the Battery: Always start by disconnecting the negative terminal of the battery to prevent electrical shocks or short circuits.

- Identify the Alternator Terminals: Refer to the wiring diagram specific to your LM7 alternator. Identify the four terminals: Battery (B+), Ground (Gnd), Ignition (IG), and Signal (S).

- Connect the Battery Terminal: Use a suitable gauge wire to connect the B+ terminal directly to the positive terminal of the battery. Ensure a secure and tight connection.

- Ground Connection: Connect the Gnd terminal to a solid ground point on the engine block or chassis to ensure effective grounding.

- Ignition and Signal Connections: To connect the IG terminal, run a wire to an ‘ignition on’ circuit, which can usually be found at the fuse box. The Signal (S) terminal can be connected to the vehicle’s computer or retained with the appropriate sensor signal wire, if applicable.

- Insulate All Connections: After making the connections, use electrical tape or heat shrink tubing to insulate all connections, preventing any chances of short circuits.

- Reconnect the Battery: Finally, reconnect the battery and start the engine. Use a multimeter to check that the alternator is charging correctly, typically delivering a voltage between 13.5 and 14.5 volts at idle.

Troubleshooting Common Issues

Despite meticulous adherence to wiring diagrams, issues can still arise. Here are some common problems related to LM7 alternator wiring and their solutions:

- No Charging Voltage:

- Check the Connections: Ensure all connections are tight and free of corrosion.

- Inspect the Fuses: A blown fuse can interrupt the charging circuit.

- Test the Alternator: Use a multimeter to determine if the alternator is functioning correctly or needs replacement.

- Intermittent Charging:

- Corroded Terminals: Clean any corroded terminals to ensure a good electrical connection.

- Worn Wiring: Inspect wiring for damage, wear, or fraying, which can lead to intermittent contact.

- Overcharging:

- Voltage Regulator Issues: If the voltage exceeds 14.5 volts significantly, the voltage regulator within the alternator may be faulty. This requires replacement for safe operation.

Conclusion

Understanding the LM7 4-pin to 1 cable alternator wiring diagram is essential for anyone looking to maintain or modify a vehicle equipped with this engine. By following proper wiring techniques and being aware of common troubleshooting methods, owners and mechanics can ensure reliable alternator performance, thus maintaining the overall health of the vehicle’s electrical system. Whether you are a seasoned professional or a DIY enthusiast, having a solid grasp of automotive wiring concepts will empower you as you take on future projects with confidence.

As always, refer to the vehicle’s manual for specifics related to wiring diagrams and configurations unique to your vehicle model. Happy wiring!